Why is Decentralisation necessary?

The supply chain industry has historically suffered from efficiency issues. It is unable to become agile, which poses a significant problem in a market in which they must be able to change their configurations quickly and continually to meet the constantly-changing dynamics of supply and demand. Another major disadvantage is that methods of communication tend to vary greatly, with some companies still relying on manual paperwork. As a result, data storage becomes locked away in proprietary systems that don’t allow for collaboration. Supply chain companies also tend to face cultural and organizational issues, such as executing operating plans due to corporate goals, board restrictions and the competitive nature of the market. $4.2 trillion is locked up in net working capital in today’s supply chains. If supply chains break from the company-centric, server-based environments in which they currently find themselves, they will become less brittle, more scalable and fully leverage the underutilized skills and assets available in modern-day business networks.

What are the benefits of using blockchain to create a Decentralised Supply system?

In a decentralized distribution model, the product moves further away from the key stakeholders at the “central” corporate office and closer to the end customer. There are a number of benefits:

• A managed decentralized logistics network is far more agile than its counterpart.

• Blockchain’s transparency helps in the careful documentation of a product’s journey from its point of origin to all its suppliers. This increases the trust among the various parties in the supply chain because all the data is visible for everyone to see.

• Blockchain’s immutability will make sure that all the records in the chain are honest and free from corruption. Plus, the strong security from its innate cryptography will eliminate unnecessary audits, saving copious amounts of time and money.

• The blockchain network can take in all participants of the supply chain network. Regardless of their geographical location, everybody will be able to connect with the blockchain.

• The utilization of blockchain also opens up the doors to future innovation.

• Each node of the supply chain can be tuned to that specific area's demand to best serve the customer base. Product levels can be distributed to locations across the country based on the volume of orders in that area.

• The ability to test systems, products, markets, and suppliers on a small scale before rolling out to the entire organization can lead to better data-driven decisions.

• “Just In Time” inventory. Being able to satisfy customers' demands through better last mile management can give businesses a competitive advantage in the marketplace. Increased technological capabilities allow systems to communicate and bring the product where it is needed when it is needed, so cash isn't parked in inventory.

• Decentralizing is an agile supply chain solution by definition, and can be done in phases. When you decide to move your business forward with a decentralized logistics solution, you can roll it out strategically.

What are the advantages of Technological Economies of Scale?

Efficiency: Before the evolution of broadband internet and cloud computing, a single centralized location made a lot of sense. The costs of servers and infrastructure could be shared across departments and economies of scale translated to dramatic cost savings. The virtual and cloud landscapes today are eliminating the need for the infrastructure we needed just five years ago. The same economies of scale that worked before to house servers internally, now make it safer to house data in the cloud with leading minds in security that would be too costly to bring in-house.

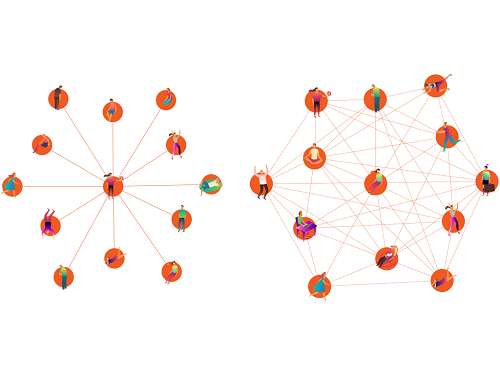

Why is decentralization better than centralization?

Companies are realizing that the cost-saving measures that once worked so well are now hindering them from being the agile supply chain that their customers are beginning to expect. The biggest reason why decentralization is better than centralization is the flexibility and data to adapt to market demands quickly. The solution to many recurring issues in supply chain primarily involves people. By creating networks of skilled individuals and decentralized autonomous organizations, immense value can be brought to companies, supply chains, and customers. These networks align economic incentives so that everyone prospers, based on their contributions of time, skill, and intellectual property. These contributions are monitored and administered through outcome-based smart contracts on the blockchain. This new vision of decentralization has the potential to radically transform the supply chain space.

How does blockchain remedy the issues of centralization in supply chains?

When looking at its positive implications, blockchain is the most logical next step for supply chain managers and logistics providers. It creates an unchangeable digital ledger that provides a record of financial transactions in chronological order. Through blockchain, massive networks of decentralized autonomous individuals and organizations can grow and operate seamlessly within a decentralized, distributed operating platform. Effective scalability. Blockchain also provides efficient and viable solutions to the aforementioned hurdles that are restricting today's supply chain. Specifically, it offers opportunities to synchronize processes that occur within supply networks, resulting in reduced Cost-of-Goods-Sold (COGS) and more cash freed from working capital. Blockchain technology and supply chain management systems were built for each other. In fact, all the flaws of the current supply chains can be easily mitigated by using the blockchain technology and blockchain can disrupt and change for the better.

What does the consumer want?

Consumers (and buyers) are increasingly concerned about where their products come from -- whether it’s ethically sourced coffee beans or authentic pharmaceutical drugs and medical devices. With the acceleration of 3D printing, replacement parts also introduce traceability and reliability concerns.

As a result, there are two drivers for implementing new technologies in today’s decentralized supply chain:

1. Ensuring compliance

2. Establishing trust

How does a decentralised supply chain mitigate threat?

In order to establish visibility and trust in the supply chain, collaborative digital platforms enabled or powered by blockchains are helping lead the way. These technologies make it easier to establish traceability, even when there’s no single source of ownership in the supply chain. For example, with blockchain, manufacturers can validate and authenticate a product’s origin, which helps to meet consumer demands for sourcing, addresses compliance needs and increases trust. Collaborative digital platforms help facilitate inter-company business processes as well as provide relevant information to the end customers in an easy to consume manner such as through mobile applications.

Collaborative digital platforms are ideal to record the full chain of custody and other traceability information necessary to ensure quality and authenticity and ultimately mitigate downtime and security risks. They also make it easier to onboard new vendors, even the small and medium-sized suppliers. Applications in the industrial, medical and high technology sectors, for example, can help meet the compliance requirements and security needs. Ensuring that all parts and products that flow through the supply chain meet those requirements demand a robust and agile method to securely verify the integrity of the physical parts and their associated data. Collaborative platforms can be used to ensure that supply chain data cannot be manipulated or altered. Verification of the physical goods and ensuring that supply chain data in fact are mapped onto the actual parts and are shared with authorized stakeholders are key ingredients of a comprehensive solution.

Creating Supply Chain Resilience - The future of the industry

In a fluid global landscape, companies must find a way to navigate fast-changing and opaque supply chains. They need to be able to adapt and respond faster to the supply chain dynamics. Having tools and capabilities to operate efficiently in “normal times” as well as effectively respond and manage disruptions in case of any of future crises is essential. To build more resiliency, organizations of all sizes should look to implement new technologies like blockchain and lean on their cloud partners and solution providers to help guide them through this journey. The need for resiliency has never been greater, and trust is the foundation. We have to collaborate across the supply chain ecosystem to build a world where trust is inherent in every part and product.